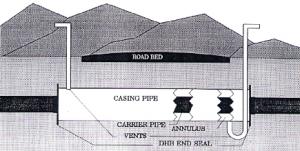

VPI CASING FILLER

VPI Casing Filler is a combination of inert gas and vapor phase inhibitor. This unique patented process removes oxygen, neutralizes water and prevents corrosion on pipes in the annular space of pipeline casings. The process features a product that is:

- WAX, GREASE & GEL FREE

- NONTOXIC

- ENVIRONMENTALLY SAFE

- INEXPENSIVE

- IN COMPLIANCE WITH DOT REGULATIONS

There is no “messy” cleanup when the job is complete or if the casing is ever removed. There is no possibility for toxics to leach into the surrounding soil. The process is designed to quickly and accurately fill the annular space with the proper amount of material. In addition to these benefits, this product and the process offers substantial cost savings compared to alternative casing fillers currently available.

An excellent method for fighting costly corrosion issues and encouraging the longest possible service life is the use of Vapor phase Corrosion Inhibitors (VpCIs). VpCIs are able to perform beyond traditional methods of corrosion protection because of their ability to work effectively in the liquid phase, vapor phase and at the sensitive liquid-vapor interface. They are also adaptable to multiple application methods including fogging, painting, hydro-testing, injection under insulation, injection into flow streams and more.

VpCI technology works by emitting a vapor from the VpCI source, whether applied in a powder, liquid or other form. When this vapor reaches a metal surface, it condenses and adsorbs — or forms a monomolecular protective layer — on the metal surface. This layer is highly hydrophobic and protects the metal from the attack of corrosive agents like moisture. It also neutralizes the electrical surface potential of the metal so that oxygen cannot interact with the metal to create a corrosion initiation site. An added benefit is that many VpCI applications have a self-replenishing capability, where new VpCI ions flow in to replace others that might be knocked away by scratching or marring of a protected surface. In the case of coatings, these VpCIs inhibit corrosion from creeping from areas of coating damage to the surrounding metal.