Monolithic Isolation Fittings

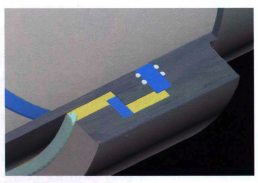

The Industry’s “Dual ‘O’Ring Seal”

Standard Tests Include:

• 100% Hydrosatic Pressure & Electrical Tests

• 100% Ultrasonic of Welds

• 100% Magnetic Particle of Welds

• 100% Dye Penetrant of Welds

| 150# ANSI Pressure Rating =285 psi |

| ElectroStop Continuous Operating Pressure = 355 psi |

| Test Pressure =540 psi |

| Working Temperature: Range =140 F. to 2120 F. (-100 C. to 1000 C.) |

| Electrical Resistance (Dry Air) =25 Mohms @ 1kv D.C. |

| Breakdown Voltage (Dry Air) =5kv @ 50Hz for 1 minute |

| 300# ANSI Pressure Rating =740 psi 400# ANSI Pressure Rating =990 psi |

| ElectroStop Continuous Operating Pressure =990 psi |

| Test Pressure =1,500 psi |

| Working Temperature: Range = 140 F. to 2120 F. (-100 C. to 1000 C.) |

| Electrical Resistance (Dry Air) =25 Mohms @ 1kv D.C. |

| Breakdown Voltage (Dry Air) =5kv @ 50Hz for 1 minute |

| 600# ANSI Pressure Rating = 1,480 psi |

| ElectroStop Continuous Operating Pressure =1,480 psi |

| Test Pressure =2,225 psi |

| Working Temperature Range = 140 F. to 2120 F. (-100 C. to 1000 C.) |

| Electrical Resistance (Dry Air) =25 Mohms @ 1kv D.C. |

| Breakdown Voltage (Dry Air) =5kv @ 50Hz for 1 minute. |

Monolitic Isolation Fitting Specification

Monolithic isolation fittings shall be boltless and completely factory assembled in accordance with the appropriate requirements of ASTM, API, DIN and BS codes. All welds shall be butt weld construction. The dielectric isolation material shall be a thermosetting fiberglass epoxy material. Sealing shall be by two (2) static, self energized “0” ring seals housed in accurately machined grooves, fully protected from cavitation in full compliance with ASME design codes. Interior and exterior coating shall be a two part epoxy with a thickness of .010 to .012″ (.25-.30mm) to within 2″ of each end. Each unit shall be tested for Electrical (@5kv, 25 Mohm), Hydraulic (@ 1.5 x O.P.) and Weld (Ultrasonic/Magnetic Particle/Dye Penetrant). The Monolithic Isolation Fitting shall be the ElectroStop™ Isolation Fitting as manufactured by Pipeline Seal & Insulator, Inc., Houston, Texas.

Quality Assurance

Each monolithic isolation fitting shall be manufactured at a facility that has a Registered ISO 9001 :2000 Quality Management System. Copy of current ISO 9001 :2000 Registration shall be provided with material submittal.

The ElectroStopTM monolithic isolation fittings will serve as a positive leak proof, long lasting block against the flow of electric current in all piping systems. When you bury the ElectroStopTM isolation fitting you bury maintenance costs forever – an especially important feature for system operators and engineers.

Eliminates Short Circuits Bolts, sleeves and washers – the major source of short circuits in most isolation assemblies are eliminated with the ElectroStopTM isolation fitting.

Eliminates Field Assembly The ElectroStopTM isolation fitting is completely factory assembled and tested. There are no flanges, gaskets, nuts, bolts, sleeves or washers to handle and consequently no fluid leaks due to improper field assembly.

Is Less Expensive Purchase the ElectroStopTM isolation fitting for less than the cost of the component parts of insulated flange assemblies in most pipe sizes. Install the ElectroStopTM isolation fitting for less than the labor costs of installing an insulated flange assembly.

Is Coated Both Internally and Externally A two part epoxy is sprayed to a thickness of .010-.012″ (.25 to .30mm) to within 2″ (50.8mm) of each weld end.

Is 100% Hydrostatically Tested All ElectroStop fittings undergo hydrostatic and cyclic pressure tests at 1.5 times rated operating pressure in accordance with the latest ANSI standards. Testing is conducted between plates or end caps to ensure the most arduous conditions

Is 100% Electrically Tested All ElectroStop fittings undergo a electrical resistance and voltage test prior to shipping.

Is Completely Weld Inspected All ElectroStopTM fitting undergo a weld inspection with combinations of ultrasonic (UT), magnetic partical (MT) and dye penetrant (LT) on all welds. In addition, X-ray tests can be conducted upon request.

Is Manufactured In Accordance With 150 9001 :2000 Quality Assurance Control over all stages of production is ensured by close adherence to an in-place and on going ISO 9001 :2000 quality assurance program which is constantly monitored and subject to periodic audit.

How To Order

To order ElectroStopTM monolithic isolation

fittings, please indicate the following:

1. Quantity

2. Nominal Pipe Size

3. ANSI, DIN, API Pressure Class or

Actual Working Pressure.

4. Pipe Grade

5. Wall Thickness

6. Temperature Limits

7. Product Conveyed

8. Contact your local distributor or

Pipeline Seal and Insulator, Inc.

PSI Flange Isolation Kits……Alternative to Monolithic Isolation Fittings. Manufactured to ISO 9001 :2000 standards, PSI Flange Isolation Kits are available for all flange sizes, types, pressure ratings and material. Type “E”, “F” and “0” Gaskets (for RTJ Flanges) are available with a variety of gasket retainers and seal elements for your application specifications. All kits can

be ordered with single washer, double washer or one piece sleeve and washer sets. For more information on Flange Isolation Kits contact PSI or visit www.pipelineseal.com for detailed specifications.

PSI Packaged Flange Isolation Kit Includes:

• Gasket

• Sleeves

• Washers