Loresco type SWK® has particle sizes ranging from 0.1 to 12mm. SWK® is heavy and sinks readily in water or light mud. It can be installed by pouring around the anodes, and tamping is not necessary.

The particles of SWK® exhibit a hard, round shape and are composed of almost solid carbon. The bulk density of SWK® is seventy pounds per cubic foot, and the porosity is forty-four percent. SWK® is a product designed specifically for use around anodes in the earth.

Its low resistivity enables intimate anode contact and assures that most electrolytic discharge will occur at the backfill periphery. According to EPA-approved leacherate tests, SWK® meets all purity requirements for materials utilized in burial.

Installation:

Loresco SWK® may be poured freely in dry applications. Tamping is not required. if SWK® is poured through water or light mud, the rate of pouring should not exceed the rate of SWK®‘s wetting and sinking. The rate of pouring through water will be approximately one hundred pounds per two minutes.

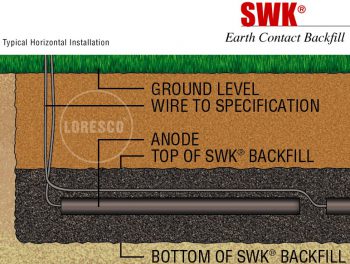

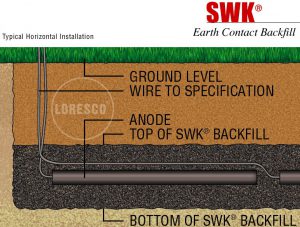

Horizontal Installation Procedure:

- Have a reasonably clean ditch (design usually calls for a ditch one foot wide).

- Pour Loresco SWK® in a continuous layer six inches deep (or as specified).

- Place anodes on top of SWK®.

- Pour SWK® in a continuous layer until anodes are covered by a six inch backfill cover (or as specified).

- Fill the remainder of the ditch as specified.

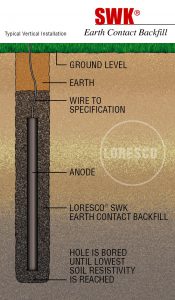

Vertical Installation Procedure:

- Have a reasonably clean hole (depth depending on soil resistivity).

- Place one foot of SWK® in bottom of hole.

- Lower and center anode in proper position.

- Pour SWK® over anode until design level is reached.

- Fill remainder of hole as design specifies.

Specifications:

- Bulk Density: 70 lbs. per cubic foot.

- Particle Sizing: Ranging from 0.1 to 12mm.

Shipping Data:

Loresco SWK® is shipped in fifty (50) pound (22.7 kg) coated, woven polypropylene bags. SWK® may be stored outside for limited periods (not to exceed four hundred hours of sunlight). Pallets are available with fifty bags per pallet. Proven export packaging is also available.