| Brand | Product | Description | Max Temp ºC | Max Temp ºF | |||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

AnodeFlex

What is AnodeFlex? AnodeFlex is an impressed current, flexible cable anode for use in cathodic protection systems for buried structures.

What is AnodeFlex? AnodeFlex is an impressed current, flexible cable anode for use in cathodic protection systems for buried structures.

Placed alongside a pipe or other buried metal structure, AnodeFlex provides uniform cathodic protection to every point, with a minimum of interference from adjacent structures.

The four basic elements of the AnodeFlex system

a Cable Anode (click to enlarge) |

|

- A special conductive polymer that seal the conductor from chemical attack, yet allows current to flow from the conductor to the environment all along its length.

- A fabric jacket to hold the coke breeze in place around de anode cable. This jacket is designed to resist electrochemical attack, but to allow current flow from de anode to the surrounding soil.

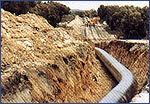

Installation

Installation of AnodeFlex is done using standard cable laying equipment, such as a hydraulic back hoe equipped with reel pay off equipment. A typical trench is only about 1 foot deep, and 6¨ wide, and no special backfill is required, Typical installation rates of 2 miles per day can be achieved.

AnodeFlex is supplied on a reel. A set of specially designed splice kits is available to handle in-line splices, branch off, and end terminations

Why use AnodeFlex systems?

AnodeFlex is used to achieve affective and homogeneous cathodic protection over the entire surface of the buried structure. Cathodic protection current should not be supplied to high demand areas at the expense of remote parts of the structure. Homogeneous distribution therefore is more important than current output.

AnodeFlex is a unique and cost effective way to keep the operation of a pipeline in compliance with cathodic protection DOT or other regulations.

- It equalizes cathodic protection at consistent levels all along the line.

- Its low overall current output will stop further coating degradation caused by cathodic disbonding when higher current output anodes are used.

- Since AnodeFlex is istalled adjacent to the pipelines, and its current output per feet is low, interference problems are significantly reduced.

- In most cases AnodeFlex can be installed in the pipeline ROW. Environmental and other ROW related problems are therefore kept to a minimum.