The ELTECH Disk Anode™ was developed specifically for the rigors of cathodically protecting dam and navigation lock gates. Since our disk anodes are designed to operate in fresh, brackish, and seawater environments, other suitable applications include: marine structures, water tanks, and vessels. With an optional primary seal spacer gasket, it can be used on the inside of pipes, tanks, or other curved surfaces.

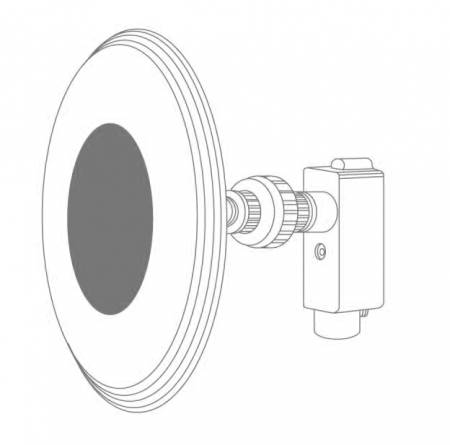

The active element in ELTECH’s Disk Anode is a 6″diameter x 1/8″ thick titanium disk with a mixed metal oxide coating. This mixed metal oxide is a crystalline, electricallyconductive coating that activates the titanium and enables it to function as an anode. When applied on titanium, the coating has an extremely low consumption rate, measured in terms of milligrams per year. As a result of this low consumption rate, the dimensions of the anode remain nearly constant throughout the design life.

The mixed metal oxide coated disk is secured into a 12″ diameter x 1/2″ thick dielectric shield made of a durable, chlorine resistant, molded FRP-vinyl ester. This FRP shield has been designed to resist damage from floating debris and ice, as well as serving to enhance the current throwing capability of the disk. The shield also minimizes excessive current damage to the coating on surrounding steel.

The low profile Disk anode fits flush with the surface, so total protrusion from the steel bulkhead is a mere 1/2″.

The coated titanium disk and shield assembly is attached to a 11/4″ diameter FRP stud via an interlocking epoxy joint. This unique joint enhances torque capability and subsequent sealing.

A 100% compressible EPDM elastomeric o-ring molded into the shield assures a watertight seal between the disk and steel bulkhead, while simultaneously allowing the shield to fit flush against the bulkhead.

Rod threads are platinum plated to prevent oxidation of the titanium – providing a low and constant contact resistance over the life of the anode. Nickel plated brass nuts further ensure a reliable, low resistance contact. And to prevent crevice corrosion of the titanium disk, a special, mixed metal oxide coating has been applied on the edges and back.

Features/Benefits:

• 6″ disk has 44% more active surface area than 5″ disk.

• A 11/4″ diameter FRP stud offers 27% greater load capacity than a comparable 1″ diameter stud.

• Platinum plated rod threads prevent titanium oxidation assuring a low and constant contact resistance.

• Increased FRP stud diameter and interlocking epoxy joint allow for a large torque capability on the jam nut threads.

• Double lock nut configuration for securing and maintaining a watertight seal.

• Molded FRP components minimize glass fiber exposure.

• Beveled edge of shield provides less resistance to water movement and minimizes debris accumulation.

• Weather-tight conduit box rotates 360° for optimum alignment with electrical conduit.

• No voltage restriction.

Current Outputs

| Freshwater | Brackish Water | Sea Water | |

| 20 Years | 1.6 amps | 1.9 amps | 3.9 amps |

| 15 Years | 1.9 | 2.3 | 4.4 |

| 10 Years | 2.4 | 2.9 | 5.1 |

ELTECH Disk Anode™ – Calculation of Current Output vs. Lifetime