Cadweld connections are the accepted method of attaching Cathodic Protection leads to pipes (steel or cast iron), tanks and structures. Cadweld connections weld the conductors and the structure to be protected so no galvanic corrosion can occur at the interface. The Cadweld process is specifically formulated to provide minimum heat effect on steel, which is especially important on thin-wall, high-stress pipes. Cadweld connections are also used for header cable taps, conductor splices and terminations, and ground rod connections

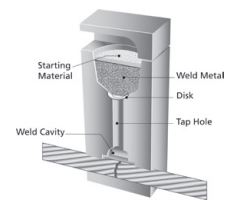

Cadweld connections are made with a semi-permanent graphite mold, which holds the conductors to be welded. Weld metal (a mixture of copper oxide and aluminum) is dumped into the top of the mold. The mold is covered and the weld metal ignited. The exothermic reaction produces molten copper, which results in a permanent, high conductivity connection.

A Cadweld Connection . . .

• Has current carrying capacity equal to that of the conductor.

• Is permanent with a low resistance connection that cannot loosen or corrode.

• Uses lightweight, inexpensive equipment.

• Requires no external source of power or heat.

• Requires no special skills.

• Can be easily checked for quality.

Types of connections:

Connection to Steel

- Tap conductor to top of horizontal steel pipe or flat surface

- Through conductor to top of horizontal STEEL pipe or flat surface

- Tap conductor to vertical STEEL pipe or flat surface.

Connections to Cast Iron

- Tap conductor to top of horizontal cast iron pipe or flat surface

- Through conductor to top of horizontal cast iron pipe or flat surface

- Tap conductor to vertical cast iron pipe or flat surface

Connections to Ground Rods

- Tap conductor to the top of a ground rod

- Through conductor to the top of a ground rod

Connections of Cable to Cable

- Tap cable to a through cable

- Splice of conductors

- Connections are available for any combination of run and tap conductor sizes

Connections of Cable to Lug

Bonds

In colder climates, water distribution pipes occasionally freeze in the winter. To thaw the ice, a high current (for example, from a welding machine) is applied to heat the pipe and thaw the ice. To accomplish this, each pipe joint must be efficiently bonded to control the electrical path and to prevent burning the pipe gaskets. 3/4” wide copper bonding straps, welded to the pipe with Cadweld connections, provide the necessary bond or current path across the pipe joints. The bonding strips have been tested at over 500 amperes.

The straps may also be used to provide continuity for Cathodic protection or grounding systems.

“Punched Strap” Bond For Steel Pipe : The Cadweld “Punched Strap” Bond allows bonding across joints of steel pipe with a bond of approximately 1/0 AWG size using a CA15 Weld Metal. This allows larger size bonds on steel pressure pipe covered by ANSI/ASME B31. The Punched Strap bond is fabricated from 1/16” x 1-1/4” soft copper, allowing easy hand forming over the pipe coupling.

Formed Terminal: Bonds with terminals formed on the ends are often used for bonding pipe joints and fittings. The formed terminal allows a smaller weld metal size to be used

Field Made Bonds: Formed Terminal Bonds may be made in the field using sleeves (one per conductor end) and forming them in the hammer dies listed.

Formed Terminal with Pigtails: Insulated, formed terminal bonds with insulated pigtails are used to bond across the joint and to bond both the middle ring and follower ring of Dresser Type Couplings.

Welders and Molds

When making a Cadweld connection, an accurate control of the Cadweld process is accomplished by using a semi-permanent graphite mold. Control is exercised over the direction and speed of the molten Cadweld weld metal flow and final shape. The graphite used in a Cadweld mold is a high temperature type that lasts for an average of 50 to 100 Cadweld connections under normal usage.

Weld Metal

Cadweld weld metal is a mixture of copper oxide and aluminum, packaged by size in plastic tubes. Each tube contains the starting material at the bottom of the plastic tube, with the Weld Metal on top. These materials are not explosive and not subject to spontaneous ignition. These containers are packaged in boxes along with metal disks. Each weld uses one disk.

Two types of Cadweld weld metal are used for Cathodic protection connections:

1. F-33 alloy is used for all connections of cable to cable and cable to steel or stainless steel pipe. The F-33 weld metal containers have green caps.

2. XF-19 alloy is used for all connections to cast iron. XF-19 weld metal containers have orange caps.

Adapter Sleeves

Small conductors may be built up to fit the opening of larger size welders using either adapter sleeves or shim stock

| Cable Size: | Use Adapter Sleeve Part No. | Use in Mold for Conductor Size: | ||

|---|---|---|---|---|

| Stranded | Solid | Stranded | Solid | |

| #12, 14 | #10, 12, 14 | CAB-133-1H | #6 | #6 |

| 10 | 8, 10 | CAB-133-1K | — | 4 |

| 7, 8, 10 | 6, 8 | CAB-133-1L | 4 | — |

| 6 | 5 | CAB-112 | 2 | — |

Adapter sleeves can be used when a limited number of connections are to be made with a smaller conductor in a larger welder.